You might already know that Panasonic Npm parts play a crucial role in your SMT production…

But what exactly makes them stand out?

Well, you’re in luck because I’ve put together a comprehensive guide.

Some tips are proven.

Some are industry insights.

Others are expert opinions.

But they’re all here.

And I’ve just updated this entire guide for 2025.

Let’s get started!

Panasonic NPM is a series of high-performance pick-and-place machines designed for surface mount technology applications. The series includes various models such as the NPM-D, NPM-D2, NPM-D3, NPM-W, NPM-W2, NPM-W2S, NPM-TT, NPM-TT2, and NPM-VF. These machines offer precise component placement, high-speed operation, and versatility, with each model catering to different production needs. The NPM series is known for its reliability, efficiency, and advanced features that enhance productivity in SMT manufacturing environments.

In this chapter, I’ll answer the question: “What Is a Panasonic Nozzle?”

I’ll also explain why Panasonic nozzles are still essential for your SMT production in 2025.

Let’s get started.

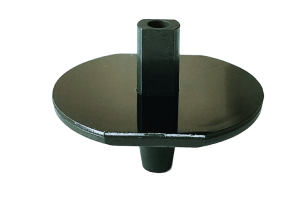

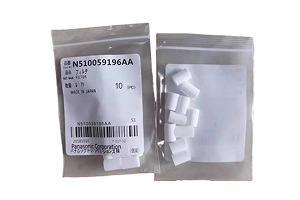

Panasonic nozzle refers to the nozzles used in Panasonic SMT equipment, typically used during the component placement process. These nozzles are part of the pick-and-place machines, helping to accurately pick and place electronic components.

Panasonic nozzles are still essential for your SMT production due to their precision, reliability, and compatibility with Panasonic’s advanced pick-and-place machines.

These nozzles, along with their holder, ensure accurate component placement, which is critical for maintaining high-quality production and minimizing defects. Regular cleaning of the nozzles helps maintain optimal performance and reduce downtime. The types of Panasonic nozzles cater to different component sizes and applications, offering flexibility in production.

While the price may vary depending on the type, investing in high-quality nozzles, such as those found in the Panasonic nozzle list, ensures long-term efficiency and reduced maintenance costs in nozzle SMT applications.

Nozzles for the Panasonic NPM series come in various configurations to suit different production needs.

These include nozzles for the 2-nozzle head and 3-nozzle head, providing flexibility for various component sizes.

There are also nozzles designed for the 8-nozzle head, enabling high-speed placement of multiple components. For larger components, nozzles for the 16-nozzle head and 12-nozzle head are available.

Additionally, special nozzles are offered for atypical parts, optimized for the 2-nozzle and 3-nozzle heads, ensuring precise handling of non-standard components.

For 2-nozzle and 3-nozzle heads, Panasonic NPM nozzles such as KXFX05KVA00, N610099244AA, N610098969AA, N610098973AA, KXFB01MHA00, and KXFB01MJA00 are designed for precise component placement. These SMT nozzles – Panasonic offer high reliability and performance, making them essential for efficient production.

With three types of nozzle options, including the Panasonic Nozzle 120N, they are compatible with Panasonic 1003 nozzles and ensure accurate handling of components. This enhances productivity and reduces downtime in SMT manufacturing processes.

1001

1002

1002N

1003

1003N

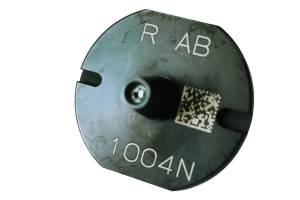

1004

1004N

1005

1006

1006N

For 8-nozzle heads, Panasonic NPM nozzles such as N610029201AB, N610119430AA, N610099376AA, N610070079AB, N610119407AA, N610040782AB, N610119487AB, N610040783AB, and N610043814AD ensure precise and efficient component placement. These panasonic SMT nozzles are made to operate under the harshest conditions, offering high reliability and optimal performance.

Providing you with quality SMT nozzles, they are ideal for high-speed SMT production with Panasonic NPM series machines. Additionally, models like Panasonic Nozzle 115S and Panasonic 120S Nozzle enhance versatility in various production settings.

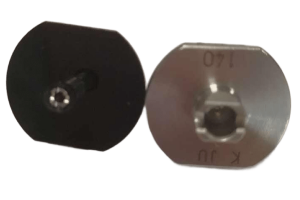

140

185

185N

230C

230CN

235CN

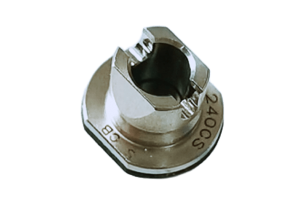

240C

226CN

240CN

For 16-nozzle and 12-nozzle heads, Panasonic NPM nozzles such as N610038265AB, N610119472AA, N610043702AB, N610040786AB, N610119479AB, N610119480AB, and N610119485AB ensure precise and reliable component placement.

These SMT nozzles – Panasonic are available in various types and listed in the catalog, designed to deliver optimal performance in high-speed SMT production. Ideal for use with Panasonic 1003 nozzles and Panasonic 1002 nozzles, they are perfectly suited for Panasonic NPM series machines.

226CS

140SN

230CSN

230CS

235CS

240CS

240CSN

For 2-nozzle and 3-nozzle heads (for atypical parts), Panasonic NPM nozzles such as KXFX05J7A00, N610127747AA, KXFX05ASA00, N610117226AA, KXFX05BVA00, N610117223AA, KXFX0558A00, N610117224AA, KXFX056AA00, N610117225AA, and KXFX05F9A00 are specifically designed to handle non-standard components.

These SMT nozzles – Panasonic ensure precision and reliability, making them ideal for handling atypical parts in Panasonic NPM series machines. Available in various types, these nozzles are listed in the catalog and can be used with Panasonic 1003 nozzles. Cleaner and holder options are also available for maintenance. The price may vary depending on the type. Additionally, 1002 nozzles are compatible for use in specific applications.

For 2-nozzle and 3-nozzle heads (for atypical parts), Panasonic NPM nozzles such as KXFX04PJA00, N610117221AA, KXFX05CMA00, KXFX056PA00, N610127619AA, KXFX0570A00, and N610127623AA are designed to handle non-standard components.

These panasonic SMT nozzles are made to operate under the harshest conditions, ensuring precision and reliability. Providing you with quality SMT nozzles, they are ideal for use in Panasonic NPM series machines, including models like NPM TT2 and NPM D3A.

With three types of nozzle options, including Panasonic Nozzle 120N, Panasonic Nozzle 115S, and Panasonic 120S Nozzle, they are well-suited for various applications such as chip mounter and feeder setups.

These nozzles ensure efficient handling of components on PC boards and in machines.

This chapter is all about teaching you the basics of Panasonic Feeder and its role in SMT production.

So if you’re new to Panasonic Npm, the sections below are a must-read.

Why?

They’ll help you get the basics down before we dive into the advanced Panasonic Feeder strategies later in this guide.

Panasonic feeders play a crucial role in the SMT (Surface Mount Technology) production process. These devices are responsible for reliably feeding parts into the pick-and-place machine, ensuring precise placement on the PCB (Printed Circuit Board).

Without a high-performance feeder, such as the NPM-WX, NPM-D3, or NPM-W2 specification, the entire production line can experience delays, component misplacements, and quality issues.

NPM Panasonic machine uses these feeders to supply parts based on instructions specified in the manual. Choosing the right feeder based on the NPM machine specification and considering factors like price and performance is vital for achieving high-quality, efficient SMT production.

In SMT production, feeders are used to supply a wide range of electronic components such as resistors, capacitors, ICs, and connectors. Their key importance lies in their ability to work seamlessly with pick-and-place machines, improving efficiency, reducing downtime, and ensuring that components are correctly fed at the required speeds.

A well-maintained and properly selected Panasonic NPM feeder cart can greatly improve the overall production process. For example, the Panasonic 8mm feeder, 32mm feeder, and Panasonic 72 mm Feeder KXFW1KS9A00 with Sensor are designed to handle different component sizes efficiently.

Additionally, the Panasonic CM402, CM602, and NPM intelligent double Emboss/Paper 8mm feeder are highly effective for precise and reliable feeding. These feeders are a key part of Panasonic modular systems, ensuring optimal performance in Panasonic SMT machines and Panasonic SMT equipment for accurate and efficient component placement.

By reducing feeder errors and enhancing the efficiency of component handling, it greatly reduces working time.

Proper feeders, like the NPM D3 Feeder, ensure that components are correctly aligned and placed on the PCB.

A reliable feeder, such as the Panasonic 24/32mm Feeder, 26mm Deep, minimizes stoppages due to jams or misfeeds, keeping the production line running smoothly.

All sizes are available in stock, and selecting the right Panasonic feeder, ensuring its proper maintenance, and understanding its specifications is vital to achieving high-quality, efficient SMT production.

Choosing the right Panasonic feeder is crucial for optimizing SMT production. Consider factors such as component size, feeder compatibility with your Panasonic NPM machines (like NPM-D3 or CM402), and feeding accuracy. Whether you need a 8mm feeder, 32mm feeder, or intelligent double emboss feeder, selecting the appropriate model based on your production requirements ensures higher efficiency, reduced downtime, and precise component placement.

Panasonic NPM series offers reliable 8mm Tape Feeders, including models like N610003478AA (Tape Feeder; 8 mm single; Type A), N610031082AA, N610031079AA, and N610031081AA.

These feeders are designed for precise component feeding in SMT production with Panasonic SMT placement machines and Panasonic SMT pick and place machines. Compatible with Panasonic NPM-W2, NPM-WX, and NPM-D3, they ensure high efficiency and minimal downtime.

Panasonic NPM feeder works seamlessly with Panasonic connect and Panasonic smart factory solutions, optimizing the production process and ensuring accurate placement of small components on the PCB. Ideal for Panasonic NPM mounters, they are also compatible with the nozzle list for efficient operation.

Panasonic NPM series offers versatile Tape Feeders (12-56mm), including models KXFW1KSCA00 and KXFW1KSDA00.

These Panasonic NPM feeders provide precise component feeding for various sizes, including 32mm feeders and Panasonic 8mm feeders, enhancing efficiency and minimizing downtime in SMT production with Panasonic NPM machines like NPM D3 and Panasonic CM402. Additionally, the Panasonic NPM feeder cart ensures smooth handling and quick feeder swaps.

Panasonic NPM series offers the Tape Feeder (72-120mm) model KXFW1KSFA00. This Panasonic SMT feeder ensures precise component feeding for larger parts, improving efficiency and minimizing downtime in SMT production.

It is compatible with Panasonic SMT line and Panasonic SMT equipment, including Standard Panasonic SMT Machine Feeder. All SMT feeders are subjected to rigorous quality control inspections. The Feeder Trolley suitable for Panasonic NPM CM Series and Panasonic Feeder Cart ensure smooth handling, enhancing performance in Panasonic NPM Series Pick and Place Machine Feeder operations.

Proper technical support and maintenance are essential to ensure the long-lasting performance and efficiency of Panasonic feeders in SMT production. Here’s a breakdown of key aspects:

Feeder Jams: Often caused by misaligned tape or component misplacement. Regular checks and alignment adjustments can prevent jams. This issue can arise in feeders such as Panasonic Tape Feeder 8mm or Panasonic 8mm Feeder.

Misfeeds: Occurs when the feeder fails to deliver components correctly. Cleaning the Panasonic SMT feeder parts and ensuring proper calibration can resolve this.

Component Feeding Errors: Often related to incorrect feeder settings or damaged components. Replacing worn-out parts (such as the Panasonic 72 mm Feeder KXFW1KS9A00 With Sensor) and recalibrating the feeder is necessary.

Panasonic offers comprehensive support for their NPM feeders, including troubleshooting, spare parts, and expert guidance.

Their after-sales service ensures quick response times, minimizing production downtime for Panasonic NPM users, including those operating models like NPM-W2 Panasonic or NPM D3A TT2.

With all SMT feeders subjected to rigorous quality control inspections, you can trust the support offered for Panasonic NPM Feeder models to keep your Panasonic NPM machine running efficiently.

Regular Cleaning: Keep the feeder components clean, especially the tape and nozzle areas. This applies to all Panasonic automatic tape feeders or Panasonic SMT Stick Feeder models.

Proper Storage: When not in use, store feeders in a clean, dry environment to prevent dust and damage. Feeder Trolley suitable for Panasonic NPM CM Series and Panasonic Feeder Cart are excellent for this purpose.

Scheduled Maintenance: Perform routine maintenance checks according to the manufacturer’s guidelines to ensure the feeder remains in optimal condition, whether for Panasonic NPM W2, Panasonic CM402, or other Panasonic NPM feeder models.

By adhering to these practices, Panasonic feeders—such as the Panasonic NPM Series Pick and Place Machine Feeder or Panasonic NPM D3—can maintain high efficiency and precision in the long term, ensuring smooth operations in SMT production.

It’s no secret that a well-designed PCB conveyor is crucial for enhancing efficiency in SMT production.

But here’s the deal:

Simply having a PCB conveyor isn’t enough to ensure seamless production.

As it turns out, certain features of the Panasonic NPM PCB Conveyor make it stand out in the market.

Here are the 3 key features that make the Panasonic NPM PCB Conveyor essential for any high-quality SMT production line:

The PCB conveyor for Panasonic NPM pick-and-place machines is designed to efficiently load, clamp, or unload PCBs during the SMT Panasonic production process.The conveyor helps streamline the movement of PCBs between different stages, ensuring consistent flow and minimizing handling errors in Panasonic SMT equipment.

It positions incoming PCBs onto the NPM machine in the correct alignment, ensuring precision during the placement process.

The conveyor often incorporates clamping mechanisms to ensure the PCBs stay securely in place while they are processed by Panasonic placement heads.

After the pick-and-place process, it unloads the finished PCBs to the next stage in the manufacturing line, optimizing Overall Equipment Effectiveness.

The conveyor’s role is crucial for automating and speeding up the process while maintaining the accuracy needed for high-quality SMT production with Panasonic NPM-D3 and NPM-W2 Panasonic models. It ensures a seamless workflow for Panasonic NPM WX or NPM-GH Panasonic, integrating smoothly with the Panasonic NPM machine for maximum throughput.

This component plays a key role in Panasonic SMT machines like the NPM-D3A, which offers a reinforced frame, advanced head, and award-winning Multi Recognition Camera. The Panasonic NPM-DX High Volume Placer and Panasonic NPM-WX Modular Placement System make the PCB conveyor indispensable in achieving high-speed, high-quality placement and optimizing Overall Equipment Effectiveness.

Panasonic NPM PCB Conveyor includes several key accessories to ensure smooth and efficient operation. These parts typically consist of:

PULLEY

RING

PULLEY

PULLEY

Support Pin

Panasonic NPM Conveyor Belts, such as N510060977AA, N510065133AA, MTNK002602AA, MTNK002604AA, MTNK002584AA, MTNK002594AA, N510059519AA, and N510059518AA, are designed to transport PCBs smoothly through the machine. These belts ensure seamless production flow, improving the efficiency of your Panasonic NPM equipment.

Belts

Belts

Belts

Belts

Belts

Panasonic NPM Sensors, such as MTNS000233AA, N510035086AB, and N510056022AA, are essential for detecting the presence of PCBs. They ensure proper alignment and positioning, enhancing the accuracy and efficiency of the Panasonic NPM machines during the production process.

FIBER

FIBER

SENSOR

SENSOR

SENSOR

SENSOR

SENSOR

MOTOR

MOTOR

BALL-SPLINE

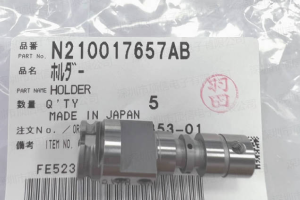

PCB Holder is essential for securely holding the PCB during the pick-and-place process in the SMT machine, especially in PCB assembly.

However, understanding its full role can be tricky.

To begin with:

How does the holder actually keep the PCB in place during the SMT process?

Or more importantly:

How does it ensure precise component placement without damaging the PCB during the assembly?

If you’ve ever wondered about these questions, this explanation will give you the answers.

Panasonic NPM PCB holder keeps the PCB in place during the SMT process through its design, which incorporates support blocks and pins. These elements securely hold the backside of the PCB, preventing any movement or shifting while the pick-and-place machine operates. The holder ensures that the PCB remains stable, which is crucial for maintaining alignment during component placement.

It ensures precise component placement by providing consistent, reliable support throughout the assembly process. By keeping the PCB stable, the holder allows the machine to accurately place components in the designated positions without causing any misalignment or damage to the PCB.

PIN

CYLINDER

VALVE

SENSOR

Block

The design minimizes the risk of the PCB being disturbed, which could result in misplaced components or damage during the process.

This includes the proper integration of parts such as MTKA032850AA, MTPA068141AA, and MTPA071568AB, ensuring seamless operation and component placement in Panasonic SMT machines and other electronics manufacturing equipment. This guarantees optimal performance and reliability in electronics machinery production.

As you know, the Panasonic NPM Supply Unit plays a vital role in ensuring smooth component placement in SMT production lines.

In fact, the supply unit not only delivers components to the Panasonic NPM pick-and-place machine but also varies in configuration depending on the machine’s specifications.

If the supply unit fails to provide consistent component delivery, it can significantly affect production efficiency.

And in this section, I’ll show you the two main components that make the Panasonic NPM Supply Unit essential for seamless component supply:

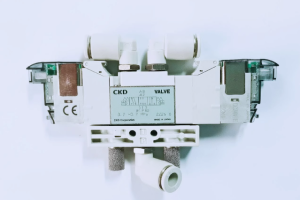

Panasonic NPM Supply Unit supplies components to be placed in the SMT process. The types of supply units vary depending on the machine specifications, with different configurations for the rear side.

Feeder carts, used on both front and rear sides, hold and organize feeders. Essential spare parts include carts, feeder components, and accessories. Ensuring compatibility with specific Panasonic NPM models is vital for performance.

ROD-END

CASTER

CASTER

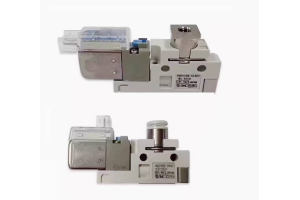

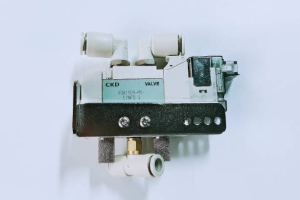

VALVE

HANDLE

BOX

SWITCH

COUPLER

CYLINDER

CABLE

SENSOR

SENSOR

SENSOR

SENSOR

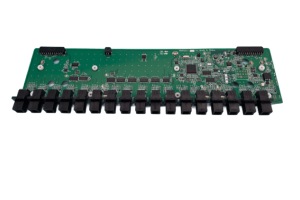

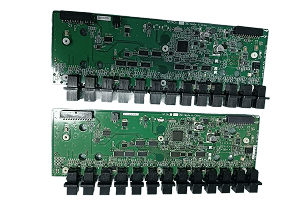

CART PCB

| Part Number A | Part Number B |

|---|---|

| N510061079AA | N210052484AA |

| N610012673AA | N210135125AA |

| N610102505AA | N210143751AB |

| KXFB02EVA01 | N510061079AA |

| N610083833AA | N610073915AB |

| KXF0CU2AA00 | N610119365AD |

| KXF0DWLEB00 |

Used on the rear side, the single tray feeder is designed for components in single-tray packaging. It offers a simple, reliable solution for fast and accurate placement, improving production speed and minimizing errors. The following part numbers are associated with this tray feeder: MTKP019537AA, MTNP003713AA, N510043445AA, N510057112AA, N610127903AA, N610127903AB, and N610074419AA.

CYLINDER

COUPLING

MOTOR-DRIVER

MOTOR

MOTOR

POWER-SUPPLY

POWER

WASHER

BELT

FAN

Choosing the right supply unit enhances productivity by ensuring smooth and efficient component feeding, reducing downtime, and minimizing errors. It optimizes the placement process, improves machine compatibility, and ensures faster, more reliable operations, ultimately boosting overall production efficiency.

To extend the lifespan of the supply unit, regular cleaning and inspection are essential. Ensure proper lubrication, handle parts carefully to avoid damage, and replace worn-out components promptly. Keeping the supply unit free of dust and debris, as well as following manufacturer guidelines for maintenance, helps maintain optimal performance and prevent costly repairs.

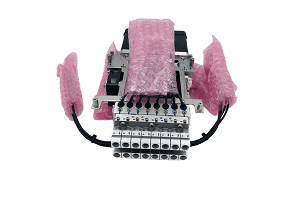

Now that you understand the basics of Panasonic NPM Placement Heads, it’s time to dive deeper into their features.

In the following sections, we will explore the different types of placement heads and how choosing the right one can significantly improve production efficiency.

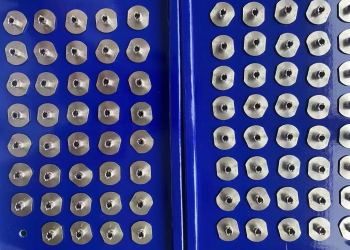

Panasonic NPM Placement Head is a crucial component in SMT production, designed for high-speed, high-precision component placement. It offers different configurations, including the lightweight 16-nozzle, 8-nozzle, and 2-nozzle heads, each catering to specific production needs.

Choosing the right placement head ensures optimal efficiency and accuracy in various manufacturing environments, especially in SMT machines and Panasonic pick and place machines. As a crucial part of surface mount technology, the correct selection enhances performance in SMT equipment, mounter machines, and mounting machines, ensuring precision and reliability in production.

Placement Heads (NPM-D3) come in various types to suit different production needs. These include the lightweight 16-nozzle head for high-speed, mass production; the lightweight 8-nozzle head for flexible, medium-speed production; and the 2-nozzle head, designed for high-precision placement of large components.

#1: PLATE

PLATE

COLLAR

HOUSING

PULLEY

PLATE

#2: BALL-SPLINE

BALL-SPLINE

16 Head Z Axis Motor

NOZZLE HOLDER

COLLAR

Cover

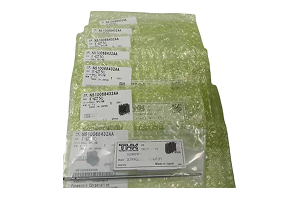

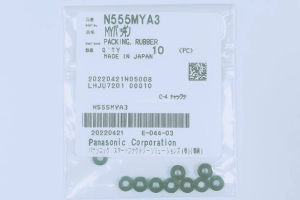

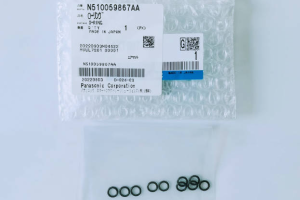

#3: PACKING

PACKING

HOLDER

BELT

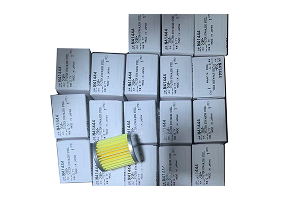

Filter

SPRING

The lightweight 8-nozzle head unit N610166414AA ensures precise component pickup and placement, enhancing flexible SMT production efficiency.

#1: PLATE

Seal Ring

BEARING

Filter holder

HOLDER

JOINT

#2: BALL-SPLINE

Nozzle Holder

BALL-SPLINE

MOTOR

MOTOR

PLATE

#3: PACKING

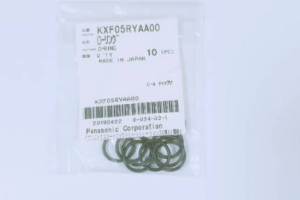

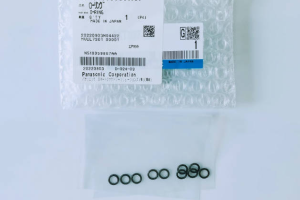

O-RING

FAN

VALVE

O-RING

BELT

#4: SENSOR

SENSOR

SENSOR

SENSOR

PCB

SPRING

The 2-nozzle head unit N610157773AA for Panasonic SMT equipment delivers high area productivity across total mounting lines.

#1: PLATE

BEARING

ARM

Coupling

PIECE

FILTER

#2: O-RING

O-RING

O-RING

Nozzle Holder

O-RING

Ball-spline

#3: CLAMP

CLAMP

PISTON

ARM

ARM

PCB

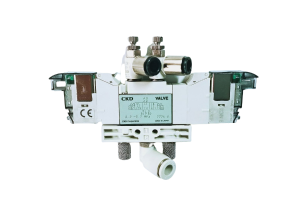

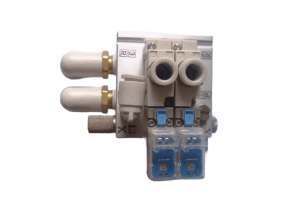

#4: VALVE

VALVE

VALVE

VALVE

VALVE

VALVE

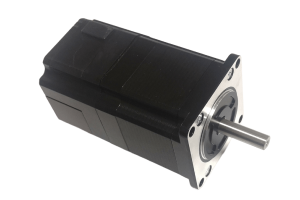

#5: MOTOR

SENSOR

SENSOR

MOTOR

MOTOR

MOTOR

The 16-nozzle head focuses on high-speed, mass production, handling small components efficiently. The 8-nozzle head balances speed and flexibility for medium-sized components. The 2-nozzle head ensures high precision, ideal for large or complex components.

These heads are supported by key components such as MTPA068141AA, MTKB000683AA, MTKB000683AA, N610097899AA, N610097899AC, and N510068432AA, which contribute to the machine’s optimal performance across different production requirements.

| Part Number 1 | Part Number 2 |

|---|---|

| MTKA032850AA | N510015534AA |

| MTKB000054AB | N610102506AA |

| MTKP0001119AF | N510068515AA |

Choosing the right placement head maximizes production efficiency by ensuring optimal component handling, speed, and precision. A 16-nozzle head enhances mass production, an 8-nozzle head offers flexibility for medium components, and a 2-nozzle head ensures accuracy for large or complex parts.

With Panasonic smart factory solutions and Panasonic SMT machines like the Panasonic NPM WX and Panasonic NPM W2, the right choice reduces downtime, improves throughput, and maintains high-quality standards across various production environments.

Let’s first take a look at the Panasonic NPM X, Y, and XY-Axis Drive Units, then dive into their parts and maintenance recommendations.

In this section, we’ll guide you on selecting the right parts and extending the lifespan of your equipment.

#1: X-Axis Drive Unit

Drives the placement head in the X direction for precise horizontal positioning.

#2: Y-Axis Drive Unit

Drives the placement head in the Y direction to ensure accurate vertical placement.

#3: XY-Axis Drive Unit

Controls simultaneous X and Y axis movements, enabling high-speed and high-precision synchronous operation.

SENSOR

STOPPER

BRACKET

CABLE-VEYOR

LED Light Control Card

The parts N510054891AA, N210190917AC, and N210190918AC are typically used in Panasonic SMT placement machines, which are known for their advanced Panasonic NPM machine specifications.

These components are essential for maintaining the high performance and precision of the Panasonic pick and place machine’s operation, contributing to the efficient movement and accurate placement of components.

Regular maintenance and prompt replacement of these parts ensure optimal machine performance and longevity, helping to maximize the efficiency of the Panasonic SMT machine.

Step #1: Regular lubrication and dust-proof maintenance to extend lifespan.

Proper lubrication ensures smooth movement of components, such as N510067048AA, N510066113AA, and N510067050AA, while dust-proof maintenance prevents dirt and debris from affecting the machine’s performance. This proactive care helps maintain optimal machine functionality and minimizes wear and tear over time.

Step #2: Common troubleshooting tips and replacement recommendations.

Regularly inspect the machine’s moving parts to ensure there are no loose or worn components in your Panasonic NPM W2 or other Panasonic NPM machines. If inaccurate placement or abnormal operation occurs, check the related motors and sensors. If any parts are damaged, promptly replace them with key components like N510067049AA and N510045363AA to ensure stable machine operation and extend its lifespan. This proactive approach is aligned with the efficiency goals of Panasonic smart factory solutions.

So that’s it for my guide to the Panasonic NPM-D3 — Main Body Unit, CPU BOX, and Compatible Parts.

I hope you found it helpful.

Now I’d like to hear from you:

Are you looking for replacement parts for the Main Body Unit or CPU BOX?

Or maybe you want to know more about compatible upgrades for your Panasonic NPM-D3 machine?

Either way, let me know by sending a quick email to jack@smtplacementsolutions.com

The NPM-D3 offers high-speed, high-precision, and flexible component placement to meet the growing demands of mass production and complex PCB assembly.

It supports a wide range of components — from 01005 chips to large connectors — making it ideal for industries such as automotive electronics, consumer electronics, telecommunications, and industrial equipment.

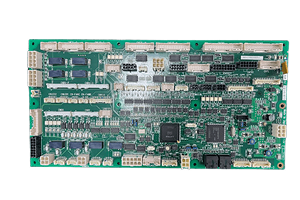

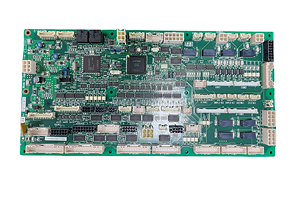

The Main Body Unit of the Panasonic NPM-D3, a Panasonic SMT placement machine, consists of key components such as the machine frame, linear motors, and vision system.

These components work together to ensure high-speed, precise component placement, making it an integral part of Panasonic smart factory solutions. The modular design allows for easy maintenance and upgrades, contributing to the Panasonic SMT machine’s long-term performance and reliability in production environments.

This flexibility and precision are key features of the Panasonic NPM series and its Panasonic SMT pick and place machine offerings.

PUMP

REGULATOR

VALVE

SENSOR

REGULATOR

SENSOR

VALVE

REGULATOR

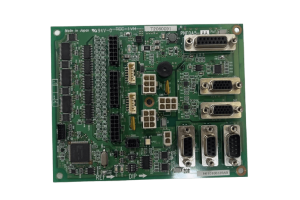

PCB

PCB

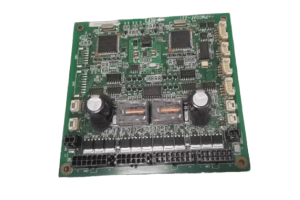

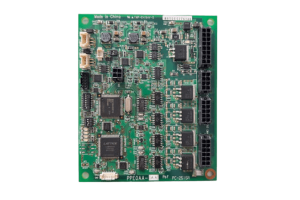

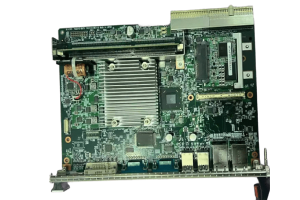

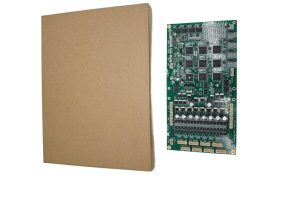

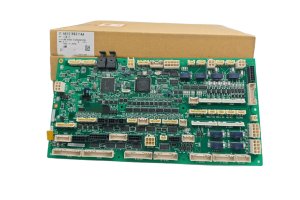

The CPU BOX in the Panasonic NPM-D3 is responsible for controlling the machine’s operations and data processing, managing the coordination of various components, and ensuring efficient and precise machine performance.

It is a core component that enables the machine’s intelligent operation and high production efficiency, making it an essential part of the Panasonic SMT line.

This functionality is critical for Panasonic SMT equipment, including the Panasonic pick and place machine and Panasonic SMT mounter, ensuring seamless integration and optimal performance in Panasonic SMT production environments.

The Panasonic NPM-D3 is compatible with various parts, including MTKP001984AA, N610121793, N610145896AA, MTKA007214AA, KXF08K7AA00, MTNC000139AA, N610154417AB, and N510025759AB.

These parts are designed to ensure optimal performance and reliability for the Panasonic NPM-D3, Panasonic NPM WX, and other Panasonic NPM machines, including the Panasonic NPM W2.

By using compatible parts, you can maintain the efficiency of your NPM SMT machine and extend the lifespan of your equipment.

It’s essential to consider the Panasonic NPM machine specification when selecting replacement parts to ensure seamless integration and continued high performance.

Power Supply

PCB

PCB

MAGNET-CONTACTOR

MAGNET-CONTACTOR

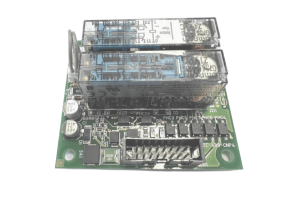

RELAY

Power

SUB BOARD

FAN

I/O BOARD

Whether you’re looking for fast production speeds or high placement accuracy, the Panasonic NPM-D3 delivers the performance needed to boost your SMT production line.

With the NPM machine price offering great value for high-performance features, the Panasonic NPM Machine is a top choice for manufacturers. You can easily find an NPM machine download for detailed specifications and updates.

The Panasonic NPM-WX, NPM-GH Panasonic, and NPM-W2 Panasonic also provide excellent options for different production needs.

Additionally, the Panasonic NPM Feeder ensures seamless integration with your NPM machines, including the NPM-D3A TT2, enhancing efficiency and accuracy.

Panasonic NPM machines require regular maintenance.

REALLY regular.

Many parts in NPM machines have lifespan limits and must be replaced to ensure optimal performance.

Replace them on time? Your machine runs smoothly.

Neglect it? Downtime will hurt production efficiency.

That’s why consumable parts are essential for keeping your NPM machine in top shape.

This guide highlights essential Panasonic NPM consumables — replacement parts, cleaning tools, and calibration jigs — to help extend your machine’s lifespan.

Panasonic NPM machines are designed for high-precision SMT production, but their performance relies heavily on the quality and condition of consumable parts.

These consumables are critical components that wear out over time and require regular maintenance to ensure the machines operate efficiently.

Regular replacement and maintenance of consumable parts in Panasonic NPM machines are crucial for optimal performance and longevity. Over time, parts like sensors, belts, and nozzles wear out and can cause machine malfunctions, leading to costly downtime.

Timely replacement of consumable parts like N610166559AA, N610157818AA, N610157825AA, N510064221AA, and N510016591AA ensures the machine operates efficiently, reduces the risk of breakdowns, and maintains production quality.

By keeping up with maintenance, you can also prevent unexpected repairs, improve machine reliability, and extend the overall lifespan of your equipment, ensuring a continuous and smooth production process.

Regularly replacing these parts helps avoid potential malfunctions and enhances the long-term performance of your panasonic pick and place machines.

Step #1: Common Parts with Lifespan Limits

Panasonic NPM machines have several consumable parts that are subject to wear and tear over time, and require replacement to maintain optimal performance. Some of the most common parts with lifespan limits include:

Power Supply

Power

Power Supply

Power Supply

MOTOR-DRIVER

Step #2: Replacement intervals and guidelines

To avoid downtime and maintain machine reliability, it is important to replace consumable parts, such as nozzles, feeders, and other components, at regular intervals.

By following these replacement guidelines for your Panasonic NPM machines—including models like NPM-TT2, NPM-D3A, NPM-W2, and NPM-D3—you can ensure consistent machine performance.

Regular maintenance of key parts such as chip mounters, nozzles, and feeders will reduce the risk of unexpected failures. Whether it’s a PCB, automation system, or the NPM-WX, replacing consumables as needed ensures optimal performance.

Leveraging tools like caeonline and Panasonic Connect for monitoring also helps streamline the process.

Step #1: Types of cleaning consumables

Cleaning consumables are essential for maintaining the performance and longevity of panasonic smt equipment. These consumables are designed to remove dirt, dust, solder paste residues, and other contaminants that can affect machine accuracy and reliability. Some common types of cleaning consumables include:

Servo Driver

GAS-SPRING

Needle

TOUCH LUBE

SWAB

FILTER

O-RING

O-RING Sealing

Filter

FILTER

Step #2: Cleaning process and frequency

Regular cleaning is essential for ensuring that Panasonic SMT placement machines, such as the NPM-W2, NPM-DX High Volume Placer, and NPM-WX Modular Placement System, operate smoothly and maintain high production standards.

A proper cleaning process helps prevent contaminants from affecting machine performance, reduces wear on components like N6100097899AC, N6100097899AA/AB, N610009394AA, N610168376AA, and N210133825AA, and extends the lifespan of the equipment.

This is especially crucial for Panasonic SMT machines and Panasonic components, as well as various SMT parts, ensuring optimal performance and reliability in production.

Panasonic offers mounting solutions for both cyberspace and physical space operations, with advanced models like NPM-VF, designed by Panasonic Connect, further enhancing placement accuracy.

Cleaning these components regularly ensures optimal machine function, reduces the risk of unexpected failures, and improves overall production efficiency.

Step #1: Available cleaning tools

Panasonic smt machine require specialized cleaning tools to maintain their performance and extend their lifespan.

cleaning tool

Nozzle cleaning Jig

Nozzle cleaning Jig

torque wrench

nozzle cleanning Jig

Step #2: How to select the right cleaning tool

Selecting the right cleaning tool for your Panasonic SMT machine is essential to ensure optimal performance and avoid damage to sensitive components.

By selecting the right cleaning tools tailored to the specific needs of your Panasonic SMT Pick and Place Machine, you can maintain machine performance, reduce downtime, and extend the lifespan of key components. For example, using parts like MTNZ001268AA, N510058942AA, and N986P752S can help clean and maintain the Panasonic NPM-D3A.

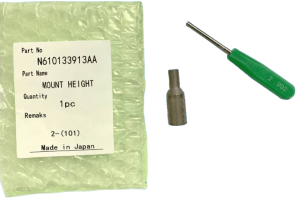

Step #1: Importance of calibration jigs

Calibration jigs play a crucial role in ensuring the accuracy and reliability of Panasonic SMT machines.

These tools are designed to align and calibrate machine components, which is essential for maintaining consistent performance, reducing errors, and ensuring high-quality production.

HOLDER grinding JIG

HOLDER grinding JIG

mount height jig

Nozzle

JIG-NOZZLE

Pick-up Height Teach Jig

Line Camera Jig

JIG Station

Adjustment Jig

HOLDER Grinding JIG

Step #2: Common jigs for NPM machines

Calibration and alignment jigs are crucial for maintaining the performance and accuracy of Panasonic NPM machines.

These jigs are specially designed for different purposes, such as nozzle calibration, feeder alignment, and machine head alignment.

Some of the most commonly used jigs for NPM machines include N210141055AB, N610114318AA, N610084605AA, N610093887AC, and N610122649AA.

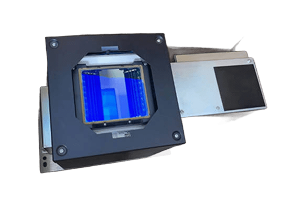

No need for a long intro here.

This section introduces the Panasonic SMT machine Multi-Recognition Camera Unit, its capability to recognize various components like Chip, IC, and Connector, spare parts supply, and its impact on machine performance.

The Multi-Recognition Camera Unit in Panasonic SMT machines identifies components with advanced optical technology, enabling accurate and efficient placement in high-speed production environments.

Panasonic SMT Multi-Recognition Camera Unit identifies various components like chips, ICs, and connectors using advanced image processing to ensure precise placement, high-speed performance, and reduced misplacement rates across SMT applications.

For machine parts, key component numbers include N610054441AA, N610054436AA, N210175876AA, and N210074890AC, which ensure optimal functionality and performance of your Panasonic SMT machines.

For Panasonic SMT machines, spare parts like MTKB000489AA, MTKB000490AA, MTKA016581AB, MTKA016000AA, and MTNG000494AA are essential for maintaining optimal performance.

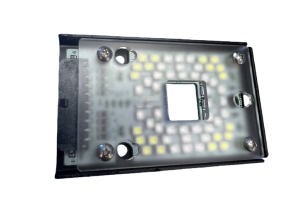

Camera

Head Camera

White LED Lighit Board

PCB

LED Lighting

These high-quality, original components ensure the reliability and longevity of your equipment, helping to reduce downtime and improve production efficiency.

You can source these parts from trusted suppliers for seamless maintenance and operations.

Panasonic SMT Multi-Recognition Camera Unit boosts Panasonic NPM pick and place machine and NPM-W2 SMT assembly machine performance, improving placement accuracy and production efficiency.

Key spare parts like MTKB000130AC, MTKB000131AA, MTKA018692AA, and MTKA006020AA ensure smooth operation.

The NPM-W2 amplifies original capabilities, offering industry-leading productivity and high-area productivity across mounting lines.

Now it’s time to explore the importance of the Panasonic NPM Nozzle Changer Unit.

The best part?

You’ll also learn how to choose the right one for your needs.

The Nozzle Changer Unit in Panasonic NPM machines plays a critical role in maintaining high efficiency, flexibility, and precision in surface mount technology (SMT) manufacturing processes. Here’s why it’s so important:

#1: Enhanced Flexibility

Supports various nozzle types, enabling quick adaptation to different components.

#2: Improved Productivity

Reduces downtime by automatically swapping nozzles, ensuring seamless operation.

#3: Precision and Accuracy

Maintains consistent placement quality, reducing defects.

#4: Optimized Maintenance

Minimizes wear by efficiently managing nozzle usage.

#5: Cost Efficiency

Extends nozzle lifespan and lowers operational costs.

#6: Compatibility with Advanced Features

Integrates with intelligent systems for enhanced automation.

The Nozzle Changer Unit in Panasonic Pick and Place Machine NPM-D3A and NPM-W2 plays a critical role in maintaining high efficiency, flexibility, and precision in surface mount technology (SMT) manufacturing processes.

As part of Panasonic Connect, it supports various nozzle types, ensuring seamless operation in chip mounter systems. This unit is essential for optimizing performance and reliability in SMT parts handling.

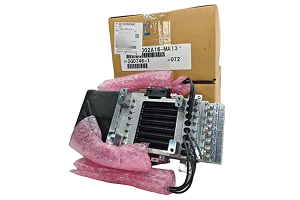

There are three types of Panasonic NPM Nozzle Changer Units: 12 Nozzle Head, 8 Nozzle Head, and 2 Nozzle Head, each designed for different production needs and efficiency levels.

8 Head Nozzle Exchange Station

16-HEAD NOZZLE CHANGER

2 Head Nozzle Exchange Station

8 Head Nozzle Exchange Station

SPRING

Choosing the right Panasonic NPM Nozzle Changer Unit depends on factors like production volume, component size, and machine compatibility. Consider your specific needs to optimize efficiency and precision.

Welcome to the Spare Parts Exhibition Hall, where we showcase high-quality spare parts for npm machines.

Explore our comprehensive selection, ensuring reliability, efficiency, and performance for your SMT production needs.

In the fast-paced world of smt assembly, Panasonic continues to lead the industry with cutting-edge pick and place machines, advanced chip mounters, and intelligent automation solutions.

The panasonic npm series, including the npm-d3a, npm-w2, npm-tt2, and npm-wx, offers high-speed performance, precision placement, and industry-leading productivity.

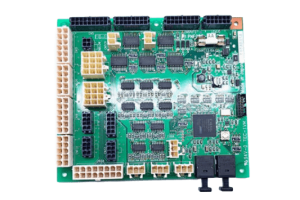

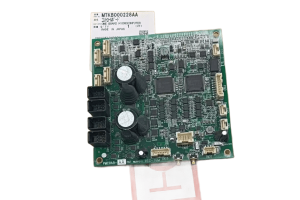

PANASONIC NPM-D3A PCB

Cpu Board HTPE0841-D8

PCB CARD BOARD

NPM D3 16 Head Card

Board card

Control Board

Camera I/F Board

PCB Control Board

Circuit Board

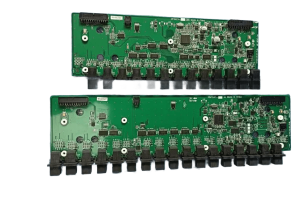

FEEDER CART BOARD

Panasonic Feeder Cart Board

BOARD MICROCOMPUTER

ILK BOARD for NPM

Interlock I/O Board

Mpm Printer Momnetum 125 NOD65 Board

DRIVER MR-J2S-70B-EE085

Control Unit for CM402

X Axis Servo Motor Driver

MR-JSS-100B-EE085

Control Unit, Y Driver

DC Motor 9.6w

Z MOTOR P50BA2003BCSPD 25W

HF-MP23B-S25 MOTOR

DC Motor 1.7W, Retracting Motor

HEAD LINEAR MOTOR

Feeder Power Line

14Pin Signal Cable

NPM Signal Line

50Pin Signal Cable

Extension Track Signal Cable

FUJI AIMEX3 FLEXIBLE TRACK

CM402 Cable Bear

CM402 Y Axis Tank Chain

Mounter Filters

BM X Y Axis Tank Chain

Bm221 Y-Axis Cable Bear

Cm602 X Axis Cable Bear

Cable Bear Y

NPM-D3 Y-axis Cable Bear

NPM-TT2 Y Cable Veyor

Multiple Step Tray Pallet

Nozzle Changer

CHART MARK BLOCK Panasonic

VALVE VQZ212-5MOZ1-M5-X550

Sprocket for CM Feeder

| No. | Part Number | No. | Part Number |

|---|---|---|---|

| 1 | N510068432AA | 8 | MTNS000432AA |

| 2 | MTNB000019AA | 9 | MTNS000433AA |

| 3 | MTNB000950AA | 10 | MTNS000434AA |

| 4 | N510069544AC | 11 | MTNS000435AA |

| 5 | N510064708AA | 12 | MTNS000436AA |

| 6 | MTNS000430AA | 13 | MTNS000437AA |

| 7 | MTNS000431AA | 14 | MTNS000438AA |

Panasonic’s npm-w2 smt assembly machine amplifies the original npm-w capabilities, providing high area productivity with total mounting lines. Designed to optimize the screen printing process, this machine ensures placement accuracy and efficiency.

The npm-w2 pick and place machine is a go-to solution for manufacturers seeking high-speed smt placement with smart factory integration.

The npm-d3a chip mounter takes high-volume placement to the next level, offering a reinforced frame, advanced head technology, and an award-winning multi recognition camera.

With 86,000 CPH (Components Per Hour) performance, the npm-d3 maximizes area productivity, making it ideal for large-scale pc board assembly.

Meanwhile, the npm-tt2 further enhances panasonic’s smt solutions by improving solder paste printer operations and feeder management.

As part of panasonic factory solutions, the npm-wx modular placement system and npm-dx high volume placer are designed for both cyberspace and physical space operations.

The npm-vf odd-form solution, developed by panasonic connect, addresses complex placement challenges, making automation more versatile.

Panasonic’s placement solutions also extend to smart factory automation, helping manufacturers improve Overall Equipment Effectiveness (OEE).

Whether using the npm-w2 specification, npm installation, or npm price evaluation, manufacturers can rely on panasonic smt machines to deliver high-speed, accurate, and reliable performance.

Panasonic’s smt nozzles, such as those used in the npm series, ensure precise component handling. The Panasonic nozzle list includes various panasonic smt nozzle types, catering to different placement needs.

Additionally, panasonic smt feeders and npm feeders are designed for seamless integration, reducing smt placement issues and optimizing the pick and place process.

From the cm88 to the npm-d3, Panasonic placement machines are built to handle demanding smt production environments.

Whether it’s the panasonic smt head, placement head, or npm-d3a cph performance, the npm series continues to maximize output using three newly designed heads, ensuring high-performance smt manufacturing.

For companies looking to invest in panasonic smt parts, whether it’s a panasonic placement machine, panasonic factory equipment, or panasonic smart factory solutions, the npm Series offers the best in automation, efficiency, and cutting-edge technology.

With panasonic’s smt solutions, the future of high-speed, accurate, and reliable smt placement is already here.

Panasonic is a global leader in the SMT industry, offering a full range of Panasonic SMT machines and Panasonic placement machines designed for speed, accuracy, and reliability.

Whether it’s a complete Panasonic SMT line, a high-performance Panasonic SMT mounter, or the advanced Panasonic NPM-TT2 SMT placement system, these solutions deliver unmatched efficiency in modern electronics manufacturing. Core components such as the Panasonic SMT head, Panasonic pick and place machine head, Panasonic placement head, and Panasonic SMT motor ensure consistent precision in every operation.

In addition, a wide selection of Panasonic SMT parts, including the Panasonic SMT belt, Panasonic SMT board, and Panasonic SMT plug-in machine options, along with the official Panasonic NPM nozzle list, provide strong support for ongoing production needs.

From reliable SMT Panasonic machines and Panasonic chip mounters to cost-effective Panasonic pick and place machine price solutions, Panasonic empowers manufacturers to achieve superior results in Panasonic SMD SMT placement with outstanding performance and durability.

© 2024 SPS Co., Limited All rights reserved.

Struggling with:

⏱ Frequent Downtime?

💸 High Maintenance Costs?

🤝 Lack of Reliable Support?

We’ve Got You Covered!

✔ Genuine, durable parts

✔ Expert support with 15+ years of experience

✔ Fast delivery, ready to ship

Request our expert services today to optimize your production line with top-quality SMT placement solutions, fast support, and reliable results!

With 15 years of experience, we provide reliable second-hand Panasonic machines, original parts, and expert support to help you improve efficiency and reduce costs.

Request our expert services today to optimize your production line with top-quality SMT placement solutions, fast support, and reliable results!

Looking for reliable SMT placement machines and parts?

We offer genuine parts and high-quality second-hand equipment from top brands like Panasonic, Yamaha, Juki, and Fuji.

✅ 15 years of industry expertise with a professional support team

✅ Extensive stock to meet your production needs

✅ Worry-free after-sales service to ensure seamless operations

Request our expert services today to optimize your production line with top-quality SMT placement solutions, fast support, and reliable results!

Request our expert services today to optimize your production line with top-quality SMT placement solutions, fast support, and reliable results!