- Latest Version of 2025

Learn Panasonic Nozzle Specifications by understanding the Lightweight 16-nozzle head V3A, 8-nozzle head, and 2-nozzle head. Explore nozzles for odd-form components, check compatibility across models, and match nozzles to your application needs to optimize your SMT performance.

Panasonic Nozzle Specifications Quick Navigation:

Panasonic Nozzle Specifications

What is a Panasonic Nozzle?

A Panasonic Nozzle is a crucial component used in SMT (Surface Mount Technology) equipment. Each nozzle head is equipped with standard nozzles that support a variety of different components. With different nozzle specifications, Panasonic ensures that its machines can handle various sizes, shapes, and types of electronic components, providing precise and efficient placement.

What is the Purpose of Panasonic Nozzle?

Panasonic Nozzles are used for precise placement of electronic components. The standard nozzles equipped on the machine support many different types of components, from standard electronic parts to odd-form components. By selecting the appropriate nozzle, Panasonic Nozzles ensure high efficiency and accuracy in SMT production lines, optimizing the manufacturing process.

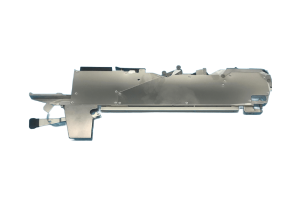

The Lightweight 16-nozzle head V3A from Panasonic Nozzle is designed to enhance SMT performance by providing high-speed and efficient component placement. This versatile nozzle head supports a wide range of components, optimizing production while maintaining precision and reducing machine downtime.

11 types come standard with the nozzles for lightweight 16-nozzle head

1. For Panasonic Nozzles with ‘C’ in the number, the nozzle tip is crafted from ceramic for durability.

2.For those with ‘N’, a 2D code is engraved on the nozzle flange to support 2D code recognition in NPM series machines.

| Panasonic Nozzle Category | Standard Model | Corresponding Model |

| 1 | 766CS | 766CSN |

| 2 | 276CS | 276CSN |

| 3 | 256CS | 256CSN |

| 4 | 225CS | 225CSN |

| 5 | 226CS | 226CSN |

| 6 | 230CS | 230CSN |

| 7 | 235CS | 235CSN |

| 8 | 240CS | 240CSN |

| 9 | 140S | 140SN |

| 10 | 101GS | 101GSN |

| 11 | 102GS | 102GSN |

3.Pickable components: Components measuring 6 x 6 mm or smaller (A x A ≤ 6 x 6)

4.In shadow detection, the size and height of components might be restricted. (This is due to the shadow cast by the components affecting nearby nozzles.)

Important Notes for Using the Lightweight 16-Nozzle Head V3A

When using the Lightweight 16-nozzle head V3A, ensure compatibility with Panasonic Nozzle specifications. Avoid exceeding component size limits to maintain precision. Regularly inspect nozzles for wear to prevent placement errors and ensure smooth operation in high-speed SMT environments.

1.Up to eight components larger than 6 x 6 mm can be picked up simultaneously using Panasonic Nozzles. These components can be arranged in two staggered patterns.

2.Nozzles adjacent to those handling components over 6 x 6 mm are suitable for picking up components up to 3 x 3 mm.

When using the Lightweight 8-nozzle head, ensure proper alignment with Panasonic Nozzles for optimal performance. Be mindful of nozzle compatibility and avoid overloading components. Regular maintenance and cleaning are essential to prevent clogs and ensure accurate component placement in high-speed operations.

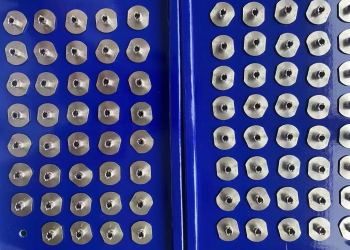

Nine types are standard for nozzles for lightweight 8-nozzle head

| Panasonic Nozzle Category | Standard Model | Corresponding Model |

| 1 | 256C | 256CN |

| 2 | 225C | 225CN |

| 3 | 226C | 226CN |

| 4 | 230C | 230CN |

| 5 | 235C | 235CN |

| 6 | 240C | 240CN |

| 7 | 140 | 140N |

| 8 | 185 | 185N |

| 9 | 199 | 199N |

Although the nine types listed above are standard Panasonic Nozzles for the lightweight 8-nozzle head, they are also compatible with the 8-nozzle head in the CM series. However, these nozzles are not compatible with the lightweight 16- or 12-nozzle heads.

Components that can be picked up:12 x 12 mm or smaller(A x A ≤ 12 x 12).

The 2-nozzle head, equipped with Panasonic Nozzles, is designed for handling larger or specialized components with high precision. It supports flexible placement of odd-form components, ensuring accuracy and adaptability in production. This head is ideal for low to medium-volume SMT processes requiring versatility.

Here are the key points to note:

Use Lightweight 16-Nozzle or 8-Nozzle Heads

To enhance production efficiency, it is recommended to use the lightweight 16-nozzle or 8-nozzle heads for mounting 0603 chips, ensuring optimal productivity.Nozzle Arrangement for Large Components

For components larger than 33 × 33 mm, install one nozzle for every two components to optimize the nozzle arrangement and performance.Improve Recognition Stability

To enhance the recognition stability of the placement head, install nozzles (reflective plates) on heads not performing pickup, based on the combination of picked components.

Key Features of the 2-Nozzle Head

The 2-nozzle head is designed for high-precision handling of larger or specialized components, making it an essential tool for accurate placement in SMT production. Equipped with Panasonic Nozzles, it offers excellent adaptability to odd-form components, ensuring flexibility for diverse production needs. Its compatibility with various SMT equipment models enhances production versatility, while its stable performance makes it ideal for low to medium-volume manufacturing. This head is a reliable solution for achieving consistent and efficient results in complex assembly processes.

| Panasonic Nozzle Category | Standard Model | Corresponding Model |

| 1 | 1599 | 1599N |

| 2 | 1001 | 1001N |

| 3 | 1002 | 1002N |

| 4 | 1003 | 1003N |

| 5 | 1004 | 1004N |

| 6 | 1005 | 1005N |

| 7 | 1006 | 1006N |

| 8 | 1551 | 1551N |

| 9 | 1479 | 1479N |

| 10 | 2405 | 2405N |

| 11 | 1404 | 1404N |

| 12 | 1421 | 1421N |

| 13 | 2467 | 2467N |

Applications of the 2-Nozzle Head

The target components for various applications include a wide range of resistor and capacitor sizes such as 0603R, 1005R, 1608R, 2012R, 3216R, and 4532R, all suitable for surface-mount technology (SMT) applications.

Additionally, there are various types of transistors and diodes like SS-Mini Tr, S-Mini Tr, Mini Tr, and others, ideal for compact electronic assemblies. Capacitors such as TAN-X (B, C, D types) and AI electrolytic capacitors (types A, B, C, D, E, F) are also commonly used in applications requiring high stability and reliability.

Other components include package types such as SOP, SOJ, PLCC, BGA, and CSP, which are essential for different types of integrated circuit (IC) packaging. These components play a critical role in a variety of electronic devices, ensuring efficiency and performance across industries.

Panasonic Nozzles for odd-form components are engineered for precision and versatility, ensuring accurate placement of irregularly shaped parts. These nozzles are tailored to handle a variety of unique components, providing reliable performance and enhancing assembly efficiency in diverse manufacturing environments.

| Panasonic Nozzle Category | Standard Model | Corresponding Model |

| 1 | 1115 | 1115N |

| 2 | 2418 | 2418N |

| 3 | 1424 | 1424N |

| 4 | 1427 | 1427N |

| 5 | 2421 | 2421N |

Panasonic Nozzle is a vital component in achieving precision in SMT (surface mount technology) assembly. One critical aspect of its operation is the alignment of nozzle length with the pickup depth of electric components. The pickup depth refers to the distance from the top surface of embossed tape to the pickup surface of the component. This measurement directly influences the performance of the nozzle and the accuracy of component placement.

When the nozzle length does not match the pickup depth, issues such as misalignment, improper placement, or even component damage can arise. Panasonic Nozzles are designed to address this challenge, offering a wide range of nozzle lengths to suit different depths and component sizes. These nozzles are crafted with precision to ensure compatibility across various electric components, even those with unique shapes or unconventional designs.

To guarantee optimal performance, Panasonic provides detailed specifications and standards for its nozzles. These guidelines allow operators to select the correct nozzle length based on the component’s pickup depth, ensuring stable operation and high assembly efficiency. With proven performance across numerous SMT systems, Panasonic Nozzles have become the trusted choice for manufacturers seeking reliability and precision.

By adhering to these operation standards, you can enhance the efficiency and accuracy of your assembly process while maintaining the quality Panasonic is known for.

Ensuring compatibility among Panasonic Nozzles is crucial for seamless performance in SMT assembly. By selecting the right nozzle for each component, manufacturers can maintain consistent accuracy and efficiency. Panasonic Nozzles are designed for flexibility, supporting a wide range of components while minimizing downtime.

The nozzles for the Panasonic NPM-D3A 2-nozzle head offer versatile compatibility with several other Panasonic models, including the CM301, CM202, CM120, and CM100. This flexibility is achieved by simply replacing orifices or attaching new ones as required. This feature allows users to adapt the same nozzles across different machine models, saving on equipment costs and reducing downtime associated with nozzle changes. The process of swapping orifices or attaching new ones is straightforward and can be done with minimal effort, ensuring that operators can quickly adjust the system to meet specific production requirements.

By using the same nozzles across multiple machines, manufacturers benefit from simplified inventory management and reduced need for storing different nozzle types. Whether dealing with standard or odd-form components, the ability to use these nozzles interchangeably across various models enhances production flexibility. Additionally, it minimizes the risk of operational interruptions, ensuring a smoother workflow. This adaptability makes Panasonic Nozzles a practical choice for diverse manufacturing environments, improving overall efficiency and cost-effectiveness.

A Comprehensive Guide to Panasonic Nozzles in SMT Applications

Panasonic nozzles are an essential component in Surface Mount Technology (SMT), playing a crucial role in the pick-and-place process. Whether you are working with Panasonic pick and place nozzles for high-precision applications or need Panasonic CM402 nozzles for specific component handling, understanding nozzle types and specifications is key to achieving optimal performance on your assembly line.

Types of Panasonic Nozzles

Panasonic nozzles come in various shapes and sizes to accommodate different components and placement tasks. Panasonic nozzle types include round, flat, and custom shapes tailored to specific components. The right nozzle ensures accurate component placement and reduces the chances of errors. For instance, high precision Panasonic nozzles are designed for delicate components that require meticulous handling, while Panasonic 350A welding nozzles are specialized for the soldering process.

Specific Models: Panasonic CM402 and CM602 Nozzles

Two of the most commonly used nozzles in Panasonic’s SMT systems are the Panasonic CM402 nozzle and the Panasonic CM602 nozzle. Both of these models are designed to handle a wide range of components. The CM402 nozzle is ideal for medium-sized components, while the CM602 nozzle offers greater flexibility, supporting a broader range of component sizes and types. These nozzles ensure high-speed pick-and-place performance and are essential for maintaining production efficiency in any assembly line.

Key Part Numbers for Panasonic Nozzles

If you’re replacing or upgrading nozzles, it’s important to refer to the correct part numbers. Some common part numbers include the KXFX037WA00 nozzle and the KXFX03DWA00 nozzle, which are compatible with specific Panasonic machines. These part numbers are essential for accurate replacement, ensuring that the new nozzles fit perfectly and maintain the desired performance levels.

Nozzle Compatibility and Suction Force

One of the most critical aspects of Panasonic nozzles is their compatibility with Panasonic SMT machines. Each model of Panasonic nozzle is designed to work seamlessly with specific machines in the Panasonic NPM series. For example, Panasonic NPM nozzles are tailored for use with the NPM series machines, ensuring precise suction force and handling for a wide variety of components.

Speaking of suction force, nozzle suction force specifications are another important consideration. Each nozzle has a specific suction strength, ensuring that it can pick up and place components without damaging them. It’s vital to select a nozzle with the correct suction force based on the component size and weight to maintain placement accuracy.

Nozzle Maintenance and Cleaning

To keep your Panasonic nozzles in optimal working condition, regular nozzle maintenance and cleaning are crucial. Over time, dust, residue, or adhesive can build up on the nozzle, affecting its performance. Regular cleaning ensures that nozzles continue to function at their best, reducing the risk of misplacement or downtime. Many Panasonic systems come with specific cleaning guides, making it easy for operators to maintain nozzles effectively.

Nozzle Selection Guide for Panasonic Machines

Choosing the right nozzle for your Panasonic assembly line nozzles is essential for maximizing efficiency. Panasonic offers a nozzle selection guide for its machines, helping users choose the appropriate nozzle based on component size, type, and machine compatibility. This guide simplifies the decision-making process, ensuring that each nozzle selected matches the production needs.

Replacement Panasonic Nozzles

When it’s time to replace a nozzle, selecting the correct replacement Panasonic nozzles is essential. Panasonic offers a wide variety of replacement nozzles that are designed for specific machine models. Whether you’re working with the NPM series, the CM series, or other Panasonic systems, choosing the right replacement nozzle will help maintain optimal performance and reduce the risk of errors.

Understanding the specifications, types, and maintenance needs of Panasonic nozzles is key to ensuring smooth operations on your assembly line. Whether you are using Panasonic pick and place nozzles, CM402 nozzles, or specialized models like the KXFX037WA00 nozzle, selecting the right nozzle based on component type and machine compatibility is crucial for high precision and efficiency.

Regular maintenance and cleaning also help extend the lifespan of nozzles, ensuring they continue to perform at their best. By staying informed about nozzle specifications and proper care, you can enhance production efficiency and reduce the risk of errors in your SMT processes.

In conclusion, mastering the Panasonic Nozzle specifications is essential for achieving optimal performance in SMT assembly. By following a step-by-step approach—familiarizing yourself with different nozzle types, understanding component compatibility, reviewing machine-specific requirements, and regularly checking nozzle maintenance—you can ensure smooth, efficient operations. With this knowledge, you will be better equipped to select the right nozzles, enhance productivity, and reduce downtime, ultimately driving improved results in your manufacturing processes.

Frequently Asked Questions

What types of nozzles are available for Panasonic SMT machines?

Panasonic offers a diverse range of nozzles for their SMT machines, catering to various component sizes and shapes. These include standard nozzles (110-140 series), small component nozzles (1001-1006 series), precision nozzles (230CS-240CS series), and special nozzles (185, 205, 206 series). Additionally, custom nozzles are available for specific component needs. This wide selection ensures that Panasonic machines can handle everything from tiny 0402 chips to large ICs and odd-form parts, providing flexibility and precision in SMT assembly processes.

How do I choose the right nozzle for my Panasonic pick and place machine?

Selecting the appropriate nozzle for a Panasonic pick and place machine involves considering several factors. First, identify your specific Panasonic machine model, such as NPM, CM402, or CM602. Then, determine the components you need to place, taking into account their size, shape, and material. Consult Panasonic’s nozzle selection guide or contact their support for guidance. For non-standard parts, custom nozzles may be required. Panasonic offers a mounting feasibility study service to help select optimal nozzles for specific needs, ensuring the best performance and accuracy in your SMT assembly process.

What are the specifications for Panasonic nozzles?

Panasonic nozzle specifications typically include the part number, compatible machine models, inner and outer diameter dimensions, material (such as ceramic or stainless steel), vacuum hole size, and maximum component size or weight capacity. For example, the 235CN nozzle (N610119496AA) has an outer diameter of 0.6mm and an inner diameter of 0.5mm. These detailed specifications help users select the most appropriate nozzle for their specific application, ensuring optimal performance and compatibility with their Panasonic SMT equipment.

How often should I replace my Panasonic nozzles?

The replacement frequency for Panasonic nozzles depends on usage, but general guidelines suggest inspecting nozzles weekly or every 140 hours of operation. Nozzles should be replaced when showing signs of wear, damage, or reduced performance. High-volume production may necessitate more frequent replacement, with some manufacturers recommending replacement every 3-6 months. Regular inspection and proactive replacement are crucial for maintaining placement accuracy and efficiency in SMT assembly processes.

What maintenance is required for Panasonic nozzles?

Maintenance of Panasonic nozzles involves regular cleaning to remove debris and contamination, inspection for wear or damage, checking vacuum performance, and proper storage when not in use. Lubrication of moving parts may be necessary as recommended by Panasonic. Calibration checks should be performed to ensure continued accuracy. Following Panasonic’s recommended maintenance schedule is essential for optimal performance and longevity of the nozzles.

How do I clean Panasonic nozzles effectively?

Effective cleaning of Panasonic nozzles can be achieved through several methods. Using specialized cleaning solutions designed for SMT nozzles is recommended. Ultrasonic cleaning provides thorough debris removal, while manual wiping with a lint-free cloth and isopropyl alcohol can be effective for routine maintenance. Compressed air can be used to clear vacuum holes. For high-volume operations, automated nozzle cleaning machines may be beneficial. It’s important to avoid abrasive materials or excessive force that could damage nozzle surfaces during the cleaning process.

Can I use a nozzle from one Panasonic model on another model?

While some nozzles may be compatible across multiple Panasonic models, it’s not recommended to interchange nozzles without verifying compatibility. Factors to consider include differences in nozzle mounting mechanisms, software and control system compatibility, and placement accuracy specifications. Always consult Panasonic documentation or support to confirm cross-model nozzle compatibility, ensuring optimal performance and preventing potential damage to your SMT equipment.

Where can I purchase replacement nozzles for Panasonic equipment?

Replacement Panasonic nozzles can be purchased from authorized Panasonic distributors, reputable SMT parts suppliers and online marketplaces specializing in SMT equipment. Some customers may be able to purchase directly from Panasonic. When sourcing replacement nozzles, it’s crucial to ensure you’re getting genuine Panasonic nozzles or high-quality alternatives to maintain equipment performance and reliability.

What are the common problems associated with Panasonic nozzles?

Common issues with Panasonic nozzles include reduced vacuum due to clogging or wear, misalignment from physical damage, inconsistent pick-up of components, and placement accuracy degradation. Sticking nozzles due to contamination and premature wear in high-volume production can also occur. Many of these issues can be prevented or mitigated through regular maintenance and timely replacement of nozzles.

How do I troubleshoot issues with my Panasonic nozzle?

To troubleshoot Panasonic nozzle problems, start by checking for visible damage or contamination and verifying vacuum pressure and flow. Inspect the nozzle tip for wear or deformation and test pick-and-place accuracy with known good components. Thoroughly clean the nozzle and retest. If issues persist, replace the nozzle. For ongoing problems, consult Panasonic support. Keeping detailed maintenance logs can help identify recurring issues and improve overall equipment performance.

What is the expected lifespan of a Panasonic nozzle?

The lifespan of a Panasonic nozzle varies based on usage, typically ranging from 3-6 months in high-volume production to up to 1 year with moderate use and proper maintenance. Ceramic nozzles may last longer than metal ones, and specialized coatings can extend lifespan. Actual lifespan depends on factors such as component types, production volume, and maintenance practices. Regular monitoring and timely replacement are key to maintaining optimal performance.

Are there custom nozzle options available for Panasonic machines?

Custom nozzle options are indeed available for Panasonic machines. Panasonic offers custom nozzle design services, and third-party manufacturers can create specialized nozzles for unique component shapes or sizes. Custom materials or coatings may be used for specific applications. Working with Panasonic or a reputable supplier to develop custom nozzles ensures that your specific needs are met, particularly for non-standard components or specialized assembly processes.

What are the benefits of using original Panasonic nozzles versus third-party options?

Original Panasonic nozzles offer several advantages, including guaranteed compatibility with Panasonic machines, consistent quality and performance, and often longer lifespans. They may be required to maintain equipment warranties and provide access to Panasonic technical support. While third-party options can be more cost-effective, they may vary in quality and compatibility. The choice between original and third-party nozzles should be based on specific requirements, budget constraints, and the importance of maintaining optimal equipment performance.